Technical Solutions

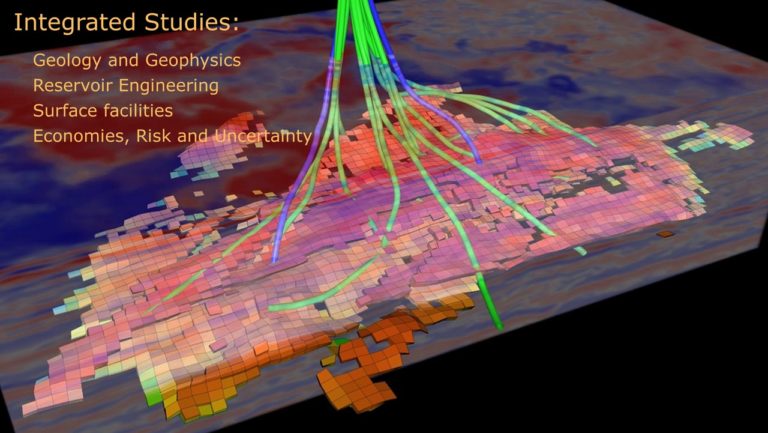

Integrated Studies

We prepare and/or review the Production Plan for complex reservoirs, using a wide angle and comprehensive perspective, including detailed characterization studies, exploitation methods, and reservoir management strategies. Most frequently, the study purposes are to increase the production expectations and reduce operating costs

All the information available since discovery is vital to understand the reservoir performance and to establish an optimum strategy for its development and continued exploitation. This results in an optimized ultimate or final recovery, leading to the best value creation for the client company

The successful integral characterization of reservoirs requires close work and cooperation by interdisciplinary teams: Geophysics, Geology, Reservoir Engineering and Infrastructure. These are key elements to correctly evaluate the reservoirs and allow the use of the adequate tools and procedures for the field’s development, yielding an optimized operation

Depending on the objective and scope of the characterization, EGEP undertakes and executes an integral study of the reservoir (subsurface-surface) which may include geologic 3D modelling and reservoir simulation for past and future performance, depending on the requirements for each case

In all cases, including either structural or stratigraphic traps, the interpretation and integration of geologic and geophysics data, the understanding of the regional geology, and all the elements of the producing system, together with the reservoir engineering and production information, allow to identify with higher certainty the exploration and development opportunities

We specialize and focus in developing and evaluating production strategies and the handling of fluids in complex accumulations, making them economically viable in areas or sectors that contain reserves categorized as non-producible with the existing strategy

Our specialists either undertake by themselves or support multidisciplinary reservoir studies, to deliver optimum drainage programs, estimating ultimate recovery under different operating scenarios and under different conditions. Thus, a reliable forecast is generally prepared for the primary, secondary and tertiary stages of the proposed production plan

We provide highly qualified professionals with decades of experience in hydrocarbons exploitation, reservoir characterization, and enhanced oil recovery (EOR) with specific experience in the proposed recovery processes, who will provide, as requested by the client, ongoing supervision of the activities scheduled for the field operation, making sure that the forecasted rates, values, costs, and economic overall performance indicators are met, in order to generate maximum value for the client

EGEP delivers detailed technical summaries in the areas of: number of wells to be drilled and workoverd, well configurations required to meet the production forecasts, optimum production strategy to meet the fluids volumetric targets, and finally the types and configuration of the surface equipment and installations required to handle the produced and injected fluids

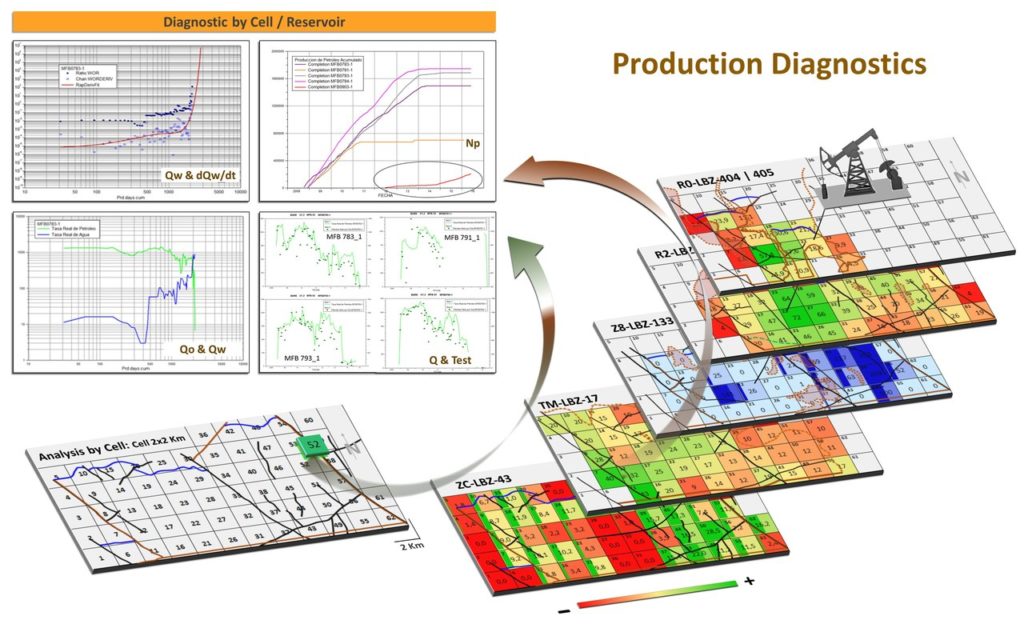

Comprehensive Reservoir Management is a dynamic process that groups a number of decisions and operations allowing to identify, quantify, develop, monitor and evaluate each stage of the development for a given reservoir or group of reservoirs

Our approach for this type of Comprehensive Reservoir Management requires the input from all professionals related to the asset: geoscientists, reservoir engineers, drilling experts, production and operations personnel, risk analysis experts and others. As a team, this group of specialists integrate their expertise under a single taskforce, in an environment suited to undertake the task, with the adequate technological tools, to understand and monitor the reservoir in a continuous manner

In this way, the following objectives are met:

- Analyze past performance and improve the reservoir production forecast

- Optimize the number and position for the drainage points

- Optimize the design for the surface facilities

- Optimize, in a continuous manner, the Production Development Plan, by monitoring a selected set of control parameters

- Monitor continuously the economic indicators for the Production Plan, as it advances in time

Comprehensive Evaluation and Optimization of Operations

We evaluate and optimize the value for the Production Plans, emphasizing their feasibility, minimizing the risk associated to the volumetric forecasted targets. Thus, we review the relevant issues associated to the technical and economic viability, for the different reservoirs, during their entire lifecycle: exploration, development, early production, late production and abandonment

We develop solutions to assure the commercial viability for the assets that comprise the value chain in exploration, development and production projects

The evaluation process starts with an initial review of all information and data available for the asset, then proceeds to the evaluation for the resources existing underground, an evaluation of the risk factors and finally to a comprehensive economic evaluation

In addition, we offer support in the processes for asset acquisition or divestment, especially in the subsurface and surface evaluation, as well as in the strategy for preparation of the offer or bid

As part of the activities related to the evaluation processes, we offer support to the following:

- Resources and Reserves evaluation for project development and investment plans

- Active support to participants in Bidding Rounds for exploration and production licenses

- Active support of virtual or physical Data Rooms, including all the items required for each asset involved

We normally prepare a technical and economical evaluation of the different production options, providing a projection for the optimum development plan for the assets, for a specific execution time frame, using different scenarios for the production targets and economic conditions, to try and maximize the project economic indicators

The economic evaluation for the asset or project is then completed, considering the income generated by the production forecast and the estimated costs

Once the economic thresholds are exceeded, an execution plan will be recommended to begin the project with the startup of the new operations or the improvement of the ongoing operation, to begin or continue with the field’s development

The process just described offers the client more control and lower uncertainty in the decision-making sequence, generating added value and trust for the investment group

There is a significant effort involved in preparing reliable production plans. This in order to forecast the future production with the low uncertainty levels required to make sound decisions

On the other hand, there is a strong dependency between the production strategy and the different types of uncertainty associated to each strategy. This in itself translates into a significant impact on the risk quantification process

In general, we clearly identify the risk issues and perform a comprehensive risk analysis on the recommended production strategy, considering that the options may vary significantly according to the scenarios considered

The comprehensive and integral risk evaluation is undertaken to quantify the impact of the decisions to be taken on the project results, to estimate the value of gathering additional information, and to quantify the value of the flexibility provided by the different production options

The risk and uncertainty analysis, when applied to the stages of initial field evaluation and development, is a complex proposition. Currently, for this analysis, the best practices are oriented towards achieving the following objectives:

- Quantification of the value of new information and the flexibility associated to it

- Production optimization under uncertainty conditions

- Risk mitigation

- Handling of risks as opportunities to increase value

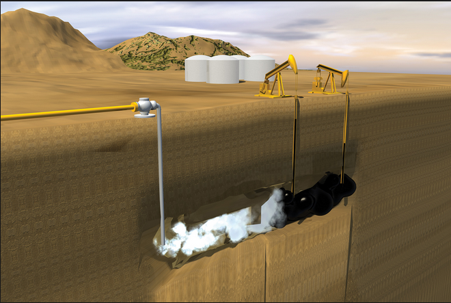

Field Tests and Pilot Projects

The detailed and timely information – obtained in field tests – is essential to evaluate and efficiently control the operations before and during the development stage in reservoirs. We have completed the successful execution of Field Tests and Pilot Projects in different locations of the world

The optimization of the true performance, for any reservoir, strongly depends on the quality of the data available and obtained from it, as well as on its correct interpretation

This precise and timely available information, is essential to monitor and control the efficiency of the operations underway, before and during the reservoir’s development

Decades of experience in the hydrocarbon industry allow us to design complete field tests or specific tests (field and laboratory) to solve problems specific to each reservoir, also valuable to monitor specific parameters for a given project

Just to mention a few of the parameters to be monitored, they are: pressures, temperatures, saturations, rates, fluid velocities, volumes and chemical compositions of produced and injected fluids, injection pressures, performance of production and injection facilities, microscopic and volumetric displacement efficiency, fluid injectivity and others

The decision to continue over a longer time in the future the hydrocarbon production from a reservoir centers around expecting favorable results from a feasible improved recovery process, and its economic potential

When it is deemed convenient to use Enhanced Oil Recovery (EOR) techniques to increase the production potential for a reservoir, designing and executing a Pilot Project is usually a must, and becomes a vital point in the decision process leading to proceed with the future production

The purpose of the pilot project is to gather information on critical variables and/or parameters for the process in the specific reservoir, to understand and model the recovery process mechanisms and to forecast its future performance

In general, the Pilot Project activities begin by identifying and selecting an area of the reservoir, representative of the average properties and conditions prevailing in the entire reservoir, so that the field test results can be then extrapolated to the rest of the reservoir. This is done with the purpose of establishing the technical and economic viability of applying the EOR scheme to the entire reservoir, in a commercial scale

Continuous Technical Support

Continuous Technical Support is an attractive option to improve the performance and competencies of the project teams for any client. Decades of experience in the hydrocarbon industry have given us the proper training to quickly develop a general overview of each operation, using past experiences and transfering to specific local situations the best operational practices. This should support the actions to be taken, in a short and medium time, to optimize the production and meet the forecasted volumetric production targets

We support and execute the field Production Plan or Plan for Production Increase, always based on the appropriate methodology using the accepted best practices

Our demonstrated and amply recognized experience in the production and handling of hydrocarbons, allows us to execute, control and evaluate under safe and reliable conditions, the entire sequence of activities for a production project, starting at the subsurface level up to the start of operation of the surface facilities

We generate the appropriate recommendations for the different project activities to be executed in an optimum and safe manner, following the proper environmental procedures, as well as honoring social responsibility criteria, lowering the associated risks and adding value to the operations and to the client

We include in our projects the comprehensive technical training for the client personnel assigned to any of our teams, in order to have a safe and productive work environment

Our on-the-job training programs are designed for the technical personnel to increase their expertise and practical experience, using the tools necessary to achieve operational excellence in their respective roles. The training programs use as instructors industry experts with at least 20 years experience in their respective fields

The training programs are properly scheduled, in order to supplement the project execution program with the personnel training effort, using the learning-by-doing approach, adjusting their timing to fit into the project schedule, optimizing the balance between the project deadlines and the training requirements

In some instances, the training can be personalized and given in the client’s offices or facilities, and this provides the opportunity to adapt its content and dates, as well as to adequately incorporate scenarios and/or data that should be restricted for commercial reasons